Why FRAMs suit data logging in EDR for airbags, ADAS

- Automotive

- 2023-09-23 21:29:21

Event data recorders (EDRs) in automotive applications like airbag safety systems and advanced driver assistance systems (ADAS) increasingly demand specialized data-logging memory devices that can instantly capture and reliably store critical data for decades.

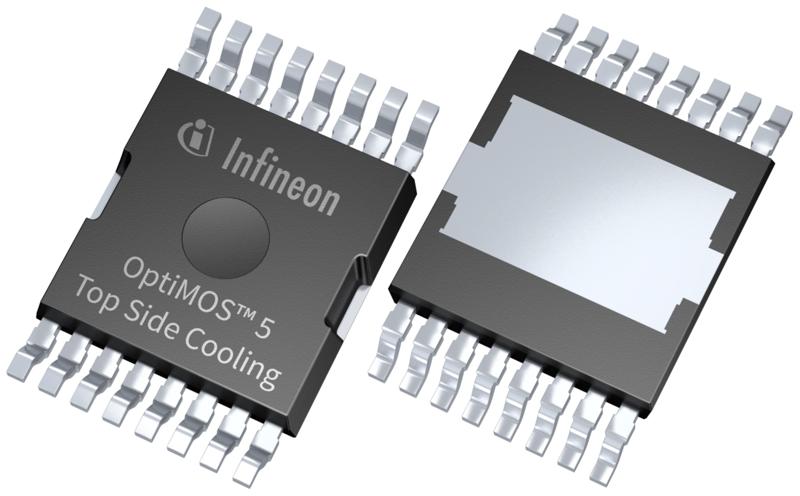

To address the need for continuous data logging in automotive designs, Infineon has expanded its portfolio by adding two new ferroelectric RAM (FRAM) memory devices in 1-Mbit and 4-Mbit densities to its EXCELON family. The German chipmaker claims that its 1-Mbit devices are the industry’s first automotive-qualified serial FRAMs.

The new FRAM devices claim to achieve continuous data logging with instant non-volatility to quickly capture pre- and post-collision event data and store instantly on power loss. As a result, it minimizes reliance on large backup capacitors that may fail during a collision or provide insufficient charge.

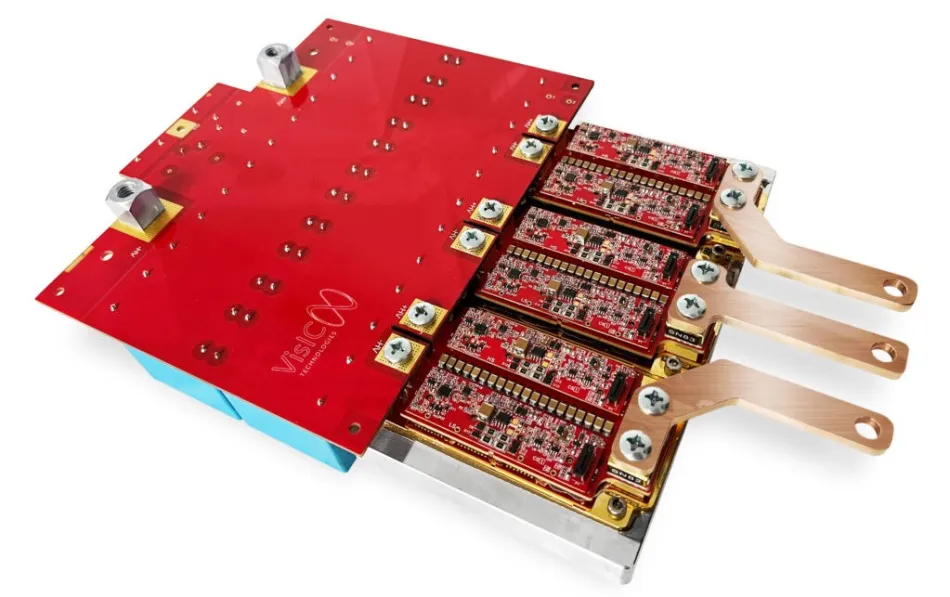

Figure 1 Data logging is expanding in automotive applications driven by increasing electrification and advanced safety systems. Source: Infineon

FRAM, a non-volatile memory that uses a ferroelectric capacitor made of lead zirconate titanate (PZT) to store data, has the characteristics of both a ROM and a RAM. So, it can be purpose-built for mission-critical data logging, and its sufficient non-volatile data storage can be tailored for automotive EDR applications.

FRAMs in airbags and ADAS

In EDR settings, Infineon’s Auto FRAM devices complement high-density storage like eMMC flash, which cannot store continuously in real-time and rely on backup capacitors to transfer after the collision, risking the loss of critical data. Continuously logging FRAM memory can also ease the load on the embedded SRAM buffer.

Figure 2 FRAMs can capture up to 20 ms of time-stamped EDR data ahead of a collision event. Source: Infineon

Take the case of airbag EDRs that capture from 5 to 20 seconds of time-stamped data metrics in a collision event to aid in accident reconstruction and vehicle safety research (Figure 2). And automakers and regulators require that EDRs record at least three events that may occur in a crash or roadway departure.

Then there are ADAS applications that capture front-facing camera images continuously for 4 seconds before and after a collision-like event to aid in accident reconstruction and vehicle safety research. Here, an FRAM can capture real-time camera images before and after collision-like events and store them instantly on power loss (Figure 3).

Figure 3 FRAMs can capture real-time camera images before and after collision-like events and store instantly on power loss. Source: Infineon

That clearly makes the case for memory densities tailored to specific use cases requiring data logging. “Data logging requirements are growing rapidly in automotive systems, as trends toward broader use of electronic systems and industry regulations have encouraged the use of high-reliability non-volatile memories in airbag safety systems, along with engine control and battery management systems,” said Ramesh Chettuvetty, VP of RAM Solutions at Infineon.

He added that the zero delay write capability of these FRAMs allows system data to be captured and recorded up to the last instant before an accident or other user-defined trigger event. Here, zero delay write means that it facilitates the write data to memory cells at bus speeds with no soak time to achieve instant non-volatility. In other words, it eliminates “soak time” by instantly backing up data on power loss.

Read/write endurance and speed

Infineon’s portfolio of automotive FRAM memory devices ranges from 4 Kbit to 16 Mbit densities. These FRAMs feature fast and reliable read/write performance at speeds up to 50 MHz in SPI mode and up to 108 MHz in quad SPI (QSPI) mode. This data transfer can match or exceed traditional parallel interfaces while reducing pin count dramatically.

Next, these FRAMs provide unlimited write cycle endurance to log data every 10 µs over 20 years. That means automotive systems like airbags and ADAS can log data continuously over a 20-year product lifespan.

Here, it’s important to note that low endurance memories like EEPROMs cannot store continuously in real-time and rely on backup capacitors to transfer after the collision, risking the loss of critical data. On the other hand, these FRAMs claim 10 trillion read/write cycles of endurance and consume 200 times lower power than EEPROMs for active writes.

Both 1 Mbit (CY15B201QN-50SXE) and 4 Mbit (CY15B204QN-40SXE) EXCELON FRAM devices are now in volume production.

Related Content

An engineers guide to FRAMFRAM MCUs For Dummies, Part 1FRAM MCUs For Dummies, Part 2: FRAM characteristics and advantagesMemory 101: What you need to know about FRAM2 Mb FRAM is ready to serve space-grade FPGAs, processorsWhy FRAMs suit data logging in EDR for airbags, ADAS由Voice of the EngineerAutomotiveColumn releasethank you for your recognition of Voice of the Engineer and for our original works As well as the favor of the article, you are very welcome to share it on your personal website or circle of friends, but please indicate the source of the article when reprinting it.“Why FRAMs suit data logging in EDR for airbags, ADAS”