AI chat tool for PCBs aims to simplify hardware design

- Analog

- 2023-09-23 21:19:41

With a design mantra, “Hardware doesn’t have to be so hard,” Flux, a supplier of browser-based PCB design tools, has unveiled the latest iteration of Copilot, a chat-based artificial intelligence (AI) design assistant integrated into the Flux PCB design tool. The upgraded Copilot leaps forward on the path to generative AI by transitioning from being a helpful guide to a proactive design partner.

Besides providing advice to design engineers, with user approval, Copilot now performs actions that pave the way to the automatic design of circuits. “Flux Copilot is becoming a truly collaborative partner in hardware design,” said Matthias Wagner, CEO of Flux. “This is a big step toward fully generative AI, reducing the time and complexity often associated with component connections.”

Flux Copilot—based on a custom-trained large language model (LLM)—is designed to understand the principles of electrical engineering and circuit design. While living inside the design project, it provides direct feedback, advice, and analysis through a simple chat interface.

How Copilot works

Copilot carries out actual connections on the schematic, helping users navigate through simple circuits or intricate arrays of unfamiliar components. It also helps users with general questions, provides guidance on specific electronics design processes, and helps build circuits for them while eliminating the need for extensive research and iteration.

“While making an integrated board is incredibly difficult, Copilot helps designers create a bunch of connections and manage control pins without reading an 80-page datasheet,” said Kerry Chayka, hardware engineer at Flux. Chayka, who started his career working on iPhone designs, learned firsthand how hardware is unnecessarily difficult.

“You are buried in tools, a siloed world that’s very hard to progress through,” he added. “On the other hand, hardware design should be creative.” While working at a startup, where it took three weeks to develop a board, when Chayka began developing boards using Flux, it took him half a day to finish the design.

“That’s how I ended up at Flux,” he said. “As a one-man hardware shop, I was able to compete with companies that had entire teams building hardware.” Chayka gave the example of automated impedance control, a complicated task designers must perform on PCBs when working on parts like HDMI bus, Ethernet, and PCIe. Flux can perform tasks like automated impedance control and automated pair routing for design engineers.

“Design engineers must ensure that high-speed buses work properly with automated impedance control, so they don’t have to worry about things such as stack-up and calculating traces with spacing,” he said. “Copilot knows what these pins are doing and how they can be connected, so design engineers don’t have to do the boilerplate work over and over again.”

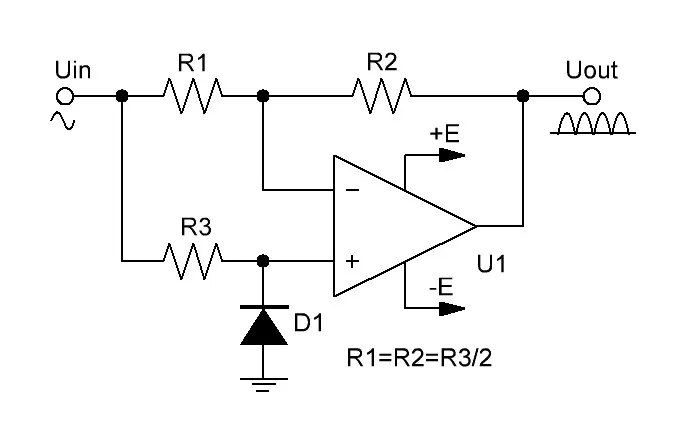

Figure 1 You can ask Copilot a bunch of questions and give a general idea of what you want to accomplish. It will provide a list of parts while helping you get started, learn things along the way, and get circuits implemented. Source: Flux

With an upgraded version, Copilot is more than a design guide. It can tell engineers what a specific pin does or explain complex circuit elements, eliminating the need to sift through pages of complex documentation. Moreover, Copilot can explain the role of parts in projects, teach users about the design, and provide a headstart for open-source hardware projects.

“If you are trying to design something similar, you can fork an open-source project, maybe add another sensor, but retain the rest of the capabilities,” Chayka noted. “That takes significantly shorter than constructing a board from scratch.”

For instance, when trying to develop an environment radiation logger, Copilot will give the list of specific parts to use and offer suggestions on developing a two-stage amplifier with 20-kHz bandwidth. Copilot can also advise what parts should be used and walk through specific electronics design processes; for example, how to connect op-amps in a configuration you want.

Community-based business model

Flux, founded in 2019 as an online hardware design platform, aims to augment engineering capabilities and thus enable professional engineers to work faster with much lower effort. “If you are a young engineer, it will enable you to do things for which you don’t have the skills,” said Jared Kofron, software engineer at Flux.

“We have an online hardware design community that offers public projects to leverage,” he added. “All projects start private by default, but some folks choose to make their projects public.” In other words, if a developer creates a part, it’s made public at Flux, and everyone can access it. Next, Flux adds real-time information about component stock and pricing to avoid supply chain issues before an engineer starts a project.

Figure 2 Copilot serves a wide range of users, from students to professional design engineers. Source: Flux

“We have a subscription model where users can subscribe for a standard monthly fee, which we want to keep low to expand access,” Kofron said. “The only thing behind the subscription is how many private projects an individual can do.”

If design engineers want to have the free version of the application, they are allowed to work on 10 private projects. If they want to go beyond that, Flux asks for a subscription; the current rate is $12 a month. Flux also has a team-tier package for companies, which is more expensive.

Initially, Flux saw a lot of interest from the hobbyist community and individual contractors. “We have also seen a lot of interest from smaller startups,” noted Kofron. “A reasonable number of large companies are also using Flux to make a difference.”

In electrical engineering, you must work at so many levels of complexity, from a high-level view to deep down at USB implementation stacks, said Chayka. “You have to understand all the complexity,” he added. “We want people who don’t have a lot of electronics design experience to be able to use the same feature set that a super pro user would use.”

Related Content

AI Must Be Secured at the Silicon LevelAI-Powered Chip Design Goes MainstreamHow generative AI puts the magic back in hardware designAI hardware acceleration needs careful requirements planningTo Conquer SoC Design Challenges, Change EDA Methods and ToolsAI chat tool for PCBs aims to simplify hardware design由Voice of the EngineerAnalogColumn releasethank you for your recognition of Voice of the Engineer and for our original works As well as the favor of the article, you are very welcome to share it on your personal website or circle of friends, but please indicate the source of the article when reprinting it.“AI chat tool for PCBs aims to simplify hardware design”