A sneak peek at next

- Sensors

- 2023-09-23 23:31:28

The use of sound waves for non-invasively visualizing a fetus in the womb, via ultrasound imaging, is widely recognized. By emitting high-frequency sound waves into the body and converting their echo into electrical signals, real-time images can be constructed. Apart from medical imaging, these sound waves find application in biometric identification and gesture recognition in automotive and virtual reality (VR) applications and various other fields.

Currently, ultrasound transducers are commonly produced using silicon semiconductor facilities. For high-resolution medical imaging with large-area coverage, large sensors are required, which is challenging for silicon-based sensors because of their high cost per mm2.

PMUT arrays for large-area imaging

In 2021, imec introduced flat panel display (FPD)-compatible piezoelectric micromachined ultrasound transducer (PMUT) arrays on glass. As a result of moving from wafer-based to FPD-compatible processes, cost-effective upscaling of ultrasound sensors was made possible.

More specifically, due to its compatibility with existing thin-film transistor backplanes and because this transducer technology is not hampered by wafer-size restrictions, large-area processing capabilities with PMUT arrays were made possible. However, the performance of the polymeric piezoelectric material was not yet sufficient for high-quality medical imaging.

Now, imec has demonstrated a second-generation PMUT array with another piezoelectrical material, AlScN. With the earlier implementation of a glass substrate instead of a crystalline silicon one, area restrictions were lifted. Additionally, this next-generation PMUT array exhibited 10 times the acoustic pressure compared to the previous generation.

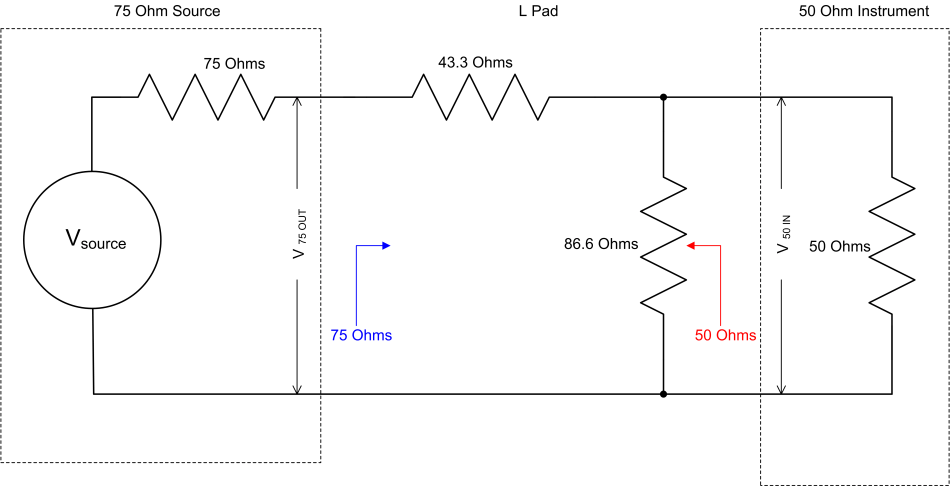

Image acquisition up to 10 cm distance is shown below with pressures above 7 kPa in water, making it suitable for high-performing ultrasound imaging (Figure 1).

Figure 1 The second-generation PMUT array has been built with piezoelectrical material AlScN. Source: imec

The array, featuring an AlScN piezoelectric layer, achieves impressive image acquisition and beam steering up to 10 cm in water. This advancement paves the way for complex ultrasound applications on curved surfaces, revolutionizing medical imaging and monitoring.

Prospects for flexible ultrasound imaging

Next steps include maturing the technology and tuning the device to specific frequencies. In doing so, this technology will enable large ultrasound arrays on for instance curved surfaces, such as sensors for the human body or car dashboards, facilitating integration of ultrasound functions on large non-planar surfaces. As a result, exciting opportunities for innovative ultrasound applications will emerge.

Figure 2 Schematic cross-sections of a PMUT process flow include (a) backplane substrate with optional TFT and/or flexible layer; (b) front-plane substrate with metal-insulator metal stack; (c) bonding of front-plane to back-plane and removal of front-plane substrate; and (d) metal via interconnect for electrical connection between front- and back-plane. Source: imec

In collaboration with Pulsify Medical, imec has already created a proof-of-concept rigid medical patch for cardiac monitoring, paving the way for non-invasive and longitudinal monitoring outside hospitals, without the need for a physician. As a result, imec’s collaboration with Pulsify Medical brings non-invasive, physician-free cardiac monitoring a step closer to reality.

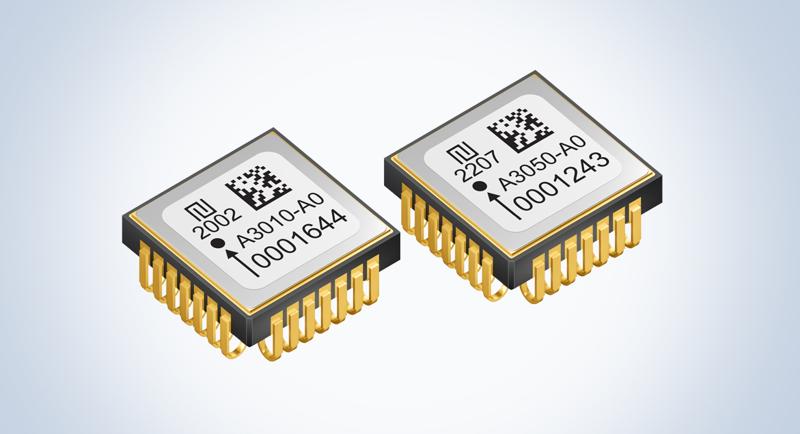

Figure 3 In the diagram outlining characteristics of PMUT elements, the inset shows a microscopy image of the fabricated PMUT and a corresponding cross-section across the cavity. Source: imec

As part of the EU-funded project ‘Listen2Future’, further development of a flexible ultrasound patch is ongoing. Listen2future is an EU-funded project addressing and benchmarking piezoelectric acoustic transducers with 27 partners across seven countries, coordinated by Infineon Technology Austria AG.

The findings are described in ‘A flat-panel-display compatible ultrasound platform’, which was presented at The Society for Information Display’s DisplayWeek 2023.

Erwin Hijzen is director of the MEMS Ultrasound program at imec.

Epimitheas Georgitzikis is R&D project leader of ‘Listen2Future’ project at imec.

Related Content

High-Performance Design for Ultrasound ImagingNew components offer flexibility in ultrasound system designTaking a multicore DSP approach to medical ultrasound beamformingimec Presents Optomechanical Ultrasound Sensor in Silicon PhotonicsSolving engineering challenges in ultrasound systems through integration and power scalingA sneak peek at next由Voice of the EngineerSensorsColumn releasethank you for your recognition of Voice of the Engineer and for our original works As well as the favor of the article, you are very welcome to share it on your personal website or circle of friends, but please indicate the source of the article when reprinting it.“A sneak peek at next”