Considerations in the selection of UV LEDs for germicidal applications

- LEDS

- 2023-09-23 23:13:23

LEDs emitting light in the range of 200 nm to 400 nm are classified as UV LEDs. Within this range, there are three bands, UV-A with wavelengths from 300 nm to 400 nm, UV-B with wavelengths between 280 nm to 315 nm, and UV-C with wavelengths from 200 nm to 280 nm. UV-C LEDs are of special interest in germicidal applications as they are positioned to replace the incumbent low pressure mercury vapor lamp. As such, a growing number of LED source and LED lighting manufacturers are offering UV-C LED products. There are several characteristics that should be considered when evaluating an LED-based system against a lighting system employing mercury vapor lamps.

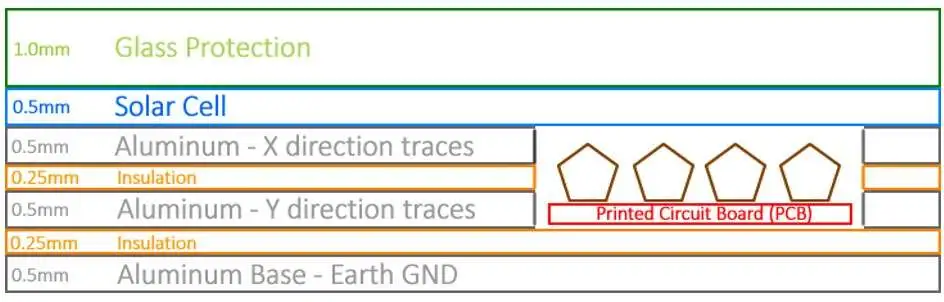

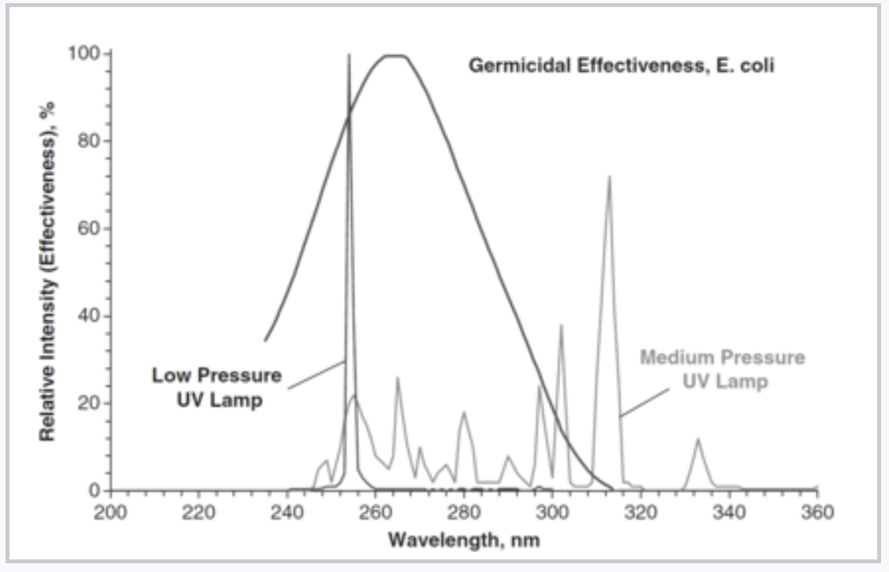

One of the most important considerations in terms of total cost of ownership is overall system efficiency. While a mercury vapor lamp may have a higher lamp efficiency, the overall system performance is dictated by several other factors as well. The first is spectral response. The spectral response of a UV-C mercury vapor lamp peaks at approximately 185 nm and 254 nm. These are fixed emissions that cannot be adjusted. Studies (here, here, and here) have shown that the optimal wavelength band for the disruption of microorganism RNA and DNA is about 265 nm (Figure 1).

UV-C LEDs are currently available at several different wavelengths including 265 nm, thereby optimizing the efficiency of the lighting system (Figure 2).

Figure 2 The UV-C LED (265 nm) spectral response compared to the E. coli germicidal effectiveness. Source: Wikipedia

A second factor, wall plug efficiency, is defined as the ratio of the output radiant power to input electrical power. Currently, the wall-plug efficiency of mercury vapor lamps exceeds that of UV-C LED-based systems. However, this advantage may be negated by the significantly lower typical lifetime of mercury vapor. A commonly accepted metric for LED luminaire lifetime is L70 (the time at which light emission has degraded to 70% of its initial value). Similarly, UV-C products are characterized by an R70 metric. The R70 of typical mercury vapor lamps ranges between 2,000 and 8,000 hours, as compared to a properly designed LED-based product which can achieve an R70 of 10,000 hours.

One last consideration in terms of overall cost of ownership is warm-up time. Mercury vapor lamp warm-up times can vary from 1 to 5 minutes, creating an incentive to leave the lamps powered at all times. By contrast UV-C LEDs, like all other LEDs, can be cycled indefinitely with instantaneous on and off times, meaning that they need only be deployed when circumstances require.

Other factors that do not directly involve cost of ownership include environmental factors (mercury versus no mercury), physical size (LED-based products can be small enough to fit into spaces that mercury vapor lamps cannot), as well as safety related considerations and required input power (high voltage for mercury vapor versus low voltage for LEDs).

In addition, there are factors to consider when comparing one UV-C LED lighting system against another. As mentioned above, UV-C LEDs can be designed for emission at essentially any wavelength. An article in the New England Journal of Medicine published in 2020 provides a virucidal efficiency curve for UV wavelengths. Unsurprisingly, the virucidal efficiency diminishes with an increasing positive or negative delta from the optimal wavelength of 265 nm. Applying this factor to the R70 of a given product provides a better picture of the effectiveness of that product over its expected lifetime.

The R70 of a product is directly related to the epitaxial material used in the LED die fabrication. UV LEDs are produced using an epitaxial material composed of gallium nitride, aluminum gallium nitride, or aluminum nitride. A higher aluminum content translates to shorter wavelengths and also lower lifetimes. Therefore, even though LEDs made without aluminum are less optimal in terms of virucidal efficiency, they can provide an overall better performance in the long-term due to a higher R70.

Speaking of R70, it is not uncommon to see an R70 specification composed of a single number for example, “R70 = 10,000 hours”. This specification is deficient because it lacks both a reference temperature and input current. The long-term performance of UV-C LEDs, like all other LEDs, is inversely related to the junction temperature of the LED die, that is, the higher the junction temperature, the more quickly the LED will degrade. Junction temperature is dependent upon both the ambient temperature and the input current. A complete R70 specification will include both of these parameters for example, R70 = 10,000 hours at 25°C and 100 mA.

One last consideration in evaluating UV-C LED-based products is the paradigm shift that these products represent. LED luminaires for general lighting—because of their endless variety of form factors, their wavelength and color tuning capabilities, and their ability to easily integrate with other building systems—have transformed our collective understanding of what a light source should look like and do. Due to the increased interest in implementation of germicidal systems, a similar transformation is poised to occur in the world of UV-C LED products. We may soon see products in all sorts of new applications in facilities and other environments, made possible by the improving performance and flexibility of UV-C LEDs.

—Yoelit Hieberthas worked in the field of LED lighting for over 10 years and has experience in both the manufacturing and end-user sides of the industry.

Related Content

Addressing design issues when working with UVC LEDsUV LEDs and DIY pest control: The practical resultsUsing LEDs for germicidal disinfectionAs UV LEDs gain in power, new apps open upConsiderations in the selection of UV LEDs for germicidal applications由Voice of the EngineerLEDSColumn releasethank you for your recognition of Voice of the Engineer and for our original works As well as the favor of the article, you are very welcome to share it on your personal website or circle of friends, but please indicate the source of the article when reprinting it.“Considerations in the selection of UV LEDs for germicidal applications”