Would better electrolytic capacitors reduce e

- LEDS

- 2023-09-23 23:13:35

There’s been a lot of attention lately on the amount of electronic waste (e-waste) we all generate. Products such as smartphones, TVs, various gadgets, and other accessories of all types are simply tossed out after a few years, either because they are obsolete due to a short lifecycle or they just fail. Much of the present-day discussion about reducing e-waste is focused on either enhancing repairability or supporting recycling.

The problem is that despite good intentions, it’s hard in practice to make low-cost, mass-markets items which are easily repaired due to basic physical access, user safety, and replacement part considerations, whether as individual components or circuit boards, as pointed out in a June 1 Wall Street Journal article Spare Parts, Fix-It-Yourself Guides Hit the Market as Brands Ponder Repairability. Recycling is also quite difficult and laden with pitfalls since electronic products have complicated assemblies and compounds of elemental substances. Consider this comparison: despite the simplicity in theory, it is surprisingly difficult in reality to recycle even basic consumables such as glass or paper. Therefore, it’s not surprising that recycling of electronics—whatever that term actually means in practice—is orders of magnitude more challenging.

But there’s another perspective: why not look to the reason why products are being tossed and try to cut that number down? Two common reasons for discarding products are that they are now obsolete—often only after a few years—or they have somehow failed and it “doesn’t pay” or it is highly impractical to try to fix them. The question is: can we reduce that failure rate?

Based on my personal experience, anecdotes from fellow engineers, and chat rooms and forums on the web, it appears there are two major causes of failure in many consumer products other than physical abuse or gross mechanical failure.

First, the rechargeable battery is no longer viable and is difficult or impossible to replace, or the power supply of an AC device has failed. Improving battery lifetime with more cycles is a subject of intense research, but making them easy to replace would be an interim solution.

Second, there are failed supplies. In nearly all cases, the root cause is that the electrolytic capacitors used for filtering of the power supply—typically, on the order of 100 μF—have failed. These are often referred to as “bulk” capacitors due to their relatively-high farad rating compared to the far-smaller bypass and timing capacitors. I can give two illustrative examples.

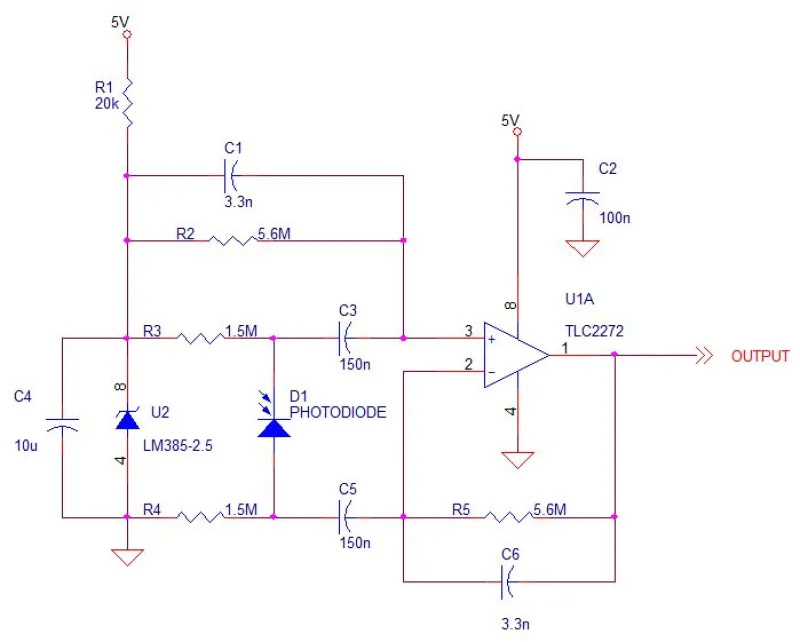

I have an inexpensive $15 AC-powered large LED clock, about five or six years old; its digit segments began getting uneven and dimmer (Figure 1). At first, I assumed the LEDs were aging, as they do, and even tried to work out the math of which segments were “on” the most over 24 hours and thus should show the most aging.

But after developing and exploring my hypothesis, I also noticed that all the digit segments were somewhat dimmer as more segments were “on” and there was also a low-rate flicker. This led me to a more-likely diagnosis: the bulk-filtering electrolytic capacitors were aging out. Obviously, this clock unit is on 24/7 and has no possibility of standby mode, which means the supply is always delivering maximum load or nearly so. A few months later, the LEDs dimmed considerably and then the unit died. Instead of throwing it out and getting a new one, I figured I’d try a fix. Fortunately, this unit was easy to open, and the capacitors were easily accessed on the PCB. I replaced them ($4) and the clock worked fine with LED segments being nice, even, and bright.

Similarly, I have a $50 digital/analog TV-converter box, which I still use with an old but functioning CFRT TV (Figure 2). Yes, I’m perhaps too attached to this circa-1996 TV, I admit it. Over the past eight or so years, the filter capacitors in this unit have failed twice, even though the converter puts itself into standby mode after a few hours of inactivity and so has a modest full-load duty cycle.

The RF-side PCB is tight but the separate board for the AC/DC supply is larger-scale, single-sided phenolic—yes, it’s still in wide use—so replacement of the capacitors required just the usual care and attention (Figure 3).

Obviously, neither of my capacitor-replacement repairs is practical for the average consumer. They require time, experience, and some skill to open the enclosure, unsolder the capacitors, and install new ones. But if these original electrolytic units were longer-lasting versions, none of this would have been necessary, and landfills would not be burdened with tossed-away units that are actually in good shape, otherwise usable, and not obsolete.

It’s one thing to argue for enhanced repair and recycling in design, but the harsh realities of modern electronics make that fairly difficult and challenging. Still, if using better capacitors on the bill of materials (BOM) adds years to the life of products, which otherwise haven’t become obsolete, wouldn’t that be a better solution, especially in these non-stressed designs? Or is thinking that will happen wishful thinking, since these better capacitors add to the cost, and consumers won’t pay even another dollar for a clock that says on the package “comes with a 10-year display life”?

Bill Schweber is an EE who has written three textbooks, hundreds of technical articles, opinion columns, and product features.

Related articles:

What’s the storage life of idled LED light bulbs?Obsolescence by design hampers computer systemsBattery recycling: A reality checkMy seven-segment LED-dimming mysterySemiconductor chip components made from wood aim to reduce e-wastePut old tech to new useEco-friendly electronics of the future will be designed to disappearWould better electrolytic capacitors reduce e由Voice of the EngineerLEDSColumn releasethank you for your recognition of Voice of the Engineer and for our original works As well as the favor of the article, you are very welcome to share it on your personal website or circle of friends, but please indicate the source of the article when reprinting it.“Would better electrolytic capacitors reduce e”