Using LEDs for germicidal disinfection

- LEDS

- 2023-09-23 23:13:48

The COVID-19 pandemic has increased the public’s awareness of UV disinfection, and that’s reflected in the growing number of LED-based products available on the market.

UV light is used to disinfect air, water, and surfaces, and the International Ultraviolet Light Association (IUVA) says it can help to mitigate the risk of transmission of the COVID-19 virus.

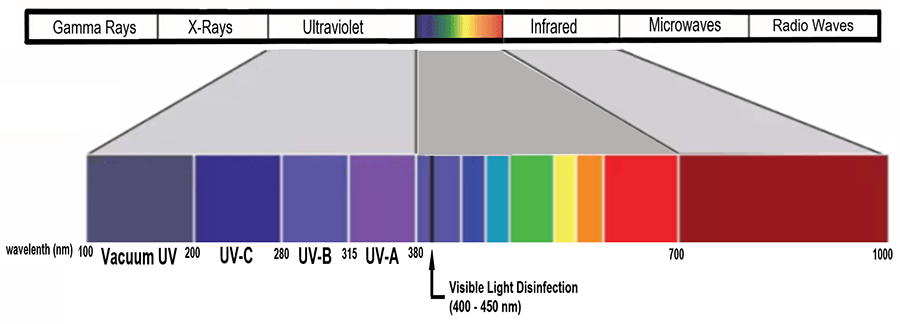

UV light is subdivided into several ranges (Figure 1). UV-A or blacklight, ranging from about 315 to 400 nm, is used for applications such as photostability testing, curing, light therapy, bug zappers, and tanning beds. Prolonged exposure to UV-A results in tanning and premature aging of the skin.

UV-B, with wavelengths ranging from 280 to 315 nm, is dangerous in that prolonged exposure has been associated with skin cancer, skin aging, and cataracts. Commercial applications include curing and light therapy in medicine.

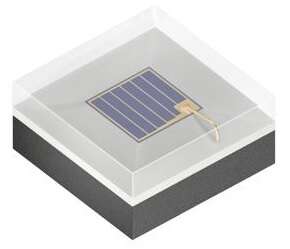

Wavelengths in the range of 200 to 280 nm are classified as UV-C. This band of UV is not associated with skin cancer because photons do not penetrate very deeply into skin, but according to IUVA, exposure can cause severe burn-like discomfort to the skin and damage to the retina of the eye. UV-C photons also interact with the RNA and DNA molecules in microorganisms, effectively destroying them. Mercury vapor lamps emitting UV-C have been used for disinfection for decades, but, as is the case with other forms of lighting, there has been a transition to products that use LED light sources.

Health experts believe that the primary transmission mode for COVID-19 is through contact with respiratory droplets either in the air or on surfaces. LED-based germicidal disinfection products currently available are geared toward surface disinfection, with more sophisticated air disinfection systems most likely available soon as the market for these devices expands. The available products feature advantages that apply to other types of LED lighting: small form factors, easy integration with other devices such as occupancy sensors, and low power requirements. But these products tend to be more expensive and more limited in terms of the surface area that can be treated in a practical timeframe.

An initial concern with the shift to LEDs was the apparent lower life compared to the incumbent mercury vapor lamps. However, this concern was based on an evaluation of continuous operation in legacy applications like sealed purification systems and did not take into account that germicidal products can (and sometimes must) be used on an intermittent basis. Like all LEDs, UV-C LEDs can be cycled virtually indefinitely with no adverse effects to light output. And unlike mercury vapor lamps, which need a warm-up time of several minutes to reach maximum light output, LED products can achieve full output levels almost instantaneously. Further, unlike mercury vapor lamps, LED-based products are able to provide only the wavelengths required for optimal results without wasting energy in the form of ineffective wavelengths.

Another concern for germicidal lighting products in general is product safety and performance claims verification. According to Carl Bloomfield, Global Director of the Commercial Infrastructure, Electrical Business Line at Intertek, their product evaluations focus on photometric parameters, germicidal claims validation, and safety compliance, as well as EMC when applicable. Standards development bodies have begun work on testing standards, but none exist as yet, so Intertek draws upon its industry and technical expertise to design evaluation protocols specific to the particular product and its intended application. Safety compliance can be especially complex as, depending on the product and its intended use, it encompasses fire risk, electric shock, mechanical hazards, optical hazards, UV light output, and ozone emissions.

In addition to products that employ UV for disinfection, a relatively new line of products is appearing, referred to as “visible light disinfection” (VLD). These products use LEDs emitting in indigo (blue-violet) wavelengths that are safe for prolonged human exposure, enabling continuous elimination of bacteria sensitive to these wavelengths.

VLD products are typically installed as part of the permanent lighting implementation in a space, sometimes combined with a white light source used for general illumination. It’s important to note that VLD disinfection is not effective against all bacteria and completely ineffective against viruses.

According to Research and Markets, the market for UV disinfection equipment is expected to grow at a compound annual growth rate of over 12% in the next five years. LED-based products are expected to play a major role in market growth due to the long life and energy efficiency of these products.

—Yoelit Hiebert has worked in the field of LED lighting for over 10 years and has experience in both the manufacturing and end-user sides of the industry.

Related articles:

Addressing design issues when working with UVC LEDsLight-based technology kills hospital superbugsClean water courtesy of LEDsUV-C LEDs disinfect and purifyHow satellite technology is fighting COVID-19Basic design considerations for germicidal products in healthcare, air filtrationUsing LEDs for germicidal disinfection由Voice of the EngineerLEDSColumn releasethank you for your recognition of Voice of the Engineer and for our original works As well as the favor of the article, you are very welcome to share it on your personal website or circle of friends, but please indicate the source of the article when reprinting it.“Using LEDs for germicidal disinfection”