Pulse power and transient loads: a very different world

- Components

- 2023-09-23 22:09:32

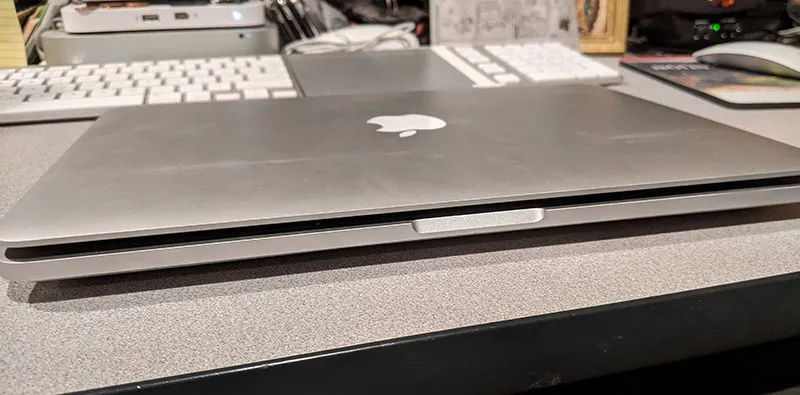

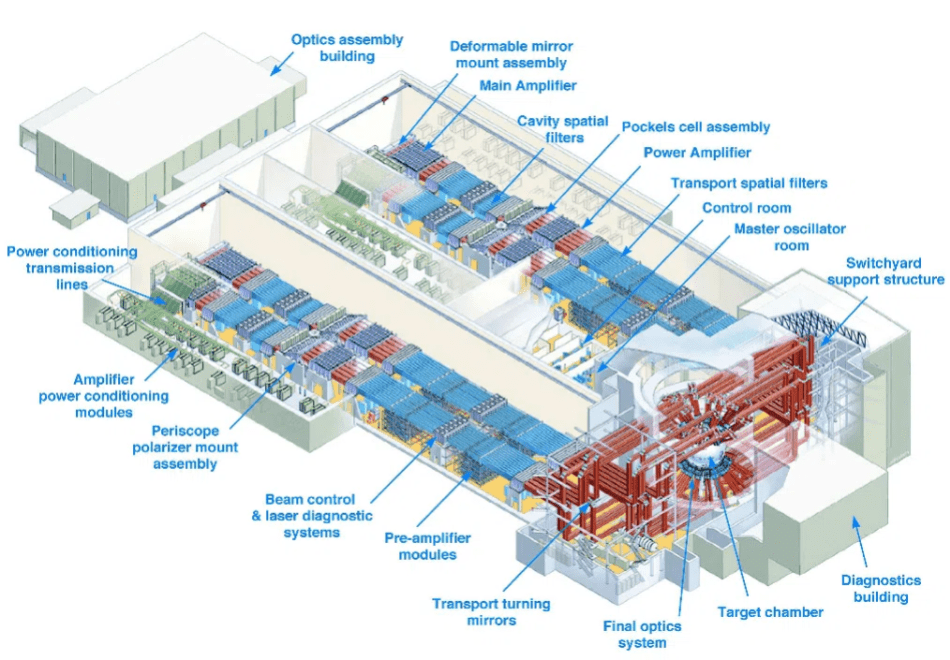

“Pulse power” has received a lot of attention and mass-media exposure recently, as demonstrated by the dramatic example in December 2022. That’s when the National Ignition Facility (NIF) at Lawrence Livermore National Laboratory focused 2.05 megajoules (MJ) of light from 192 lasers onto a tiny capsule of fusion fuel, Figure 1. This initiated an explosion in the target that produced 3.15 MJ of energy—more energy at the output than the input, and the first time the output energy exceeded the input. Although the pulse was just a few nanoseconds long, the peak-power number was also impressive at 500 terawatts.

Figure 1 The NIF fusion arrangement is definitely not a benchtop or DIY power project: the 10-meter diameter target chamber gives a sense of the scale for the facility. Source: National Ignition Facility/Lawrence Livermore National Laboratory

There’s another consideration in this story of fusion power and energy input and output: efficiency. The lasers themselves are very inefficient and converted only about 1% of their input power into lased output light.

The NIF project is an extreme example of pulsed power. That phrase usually refers to the science and technology of accumulating energy over a relatively long period of time and releasing it as a high-power pulse composed of high voltage and current but over a short period of time. It often has extremely high power but moderately low energy. Applications of pulsed power include recycling, energy research, laser-based weapons, electromagnetic launchers for aircraft, material processing, medical treatments and systems, and food and agriculture.

Although we tend to associate conventional power sources and supplies with a somewhat more “steady-state” power delivery, there are many applications and situations which call for pulse-like performance. For example, repetitively pulsed lasers used for welding typically need power on the order of one kilowatt with a pulse repetition rate of about 1000 pulses per second.

Designing a supply which can deliver pulsed power, where the output voltage and/or current must ramp from idle to full in a few milliseconds or even microseconds, is a challenge. This pulsed power is usually produced by transferring energy stored in capacitors and inductors to a load very quickly via switching devices, Figure 2, or topologies such as Marx generators.

Figure 2 Pulse power usually starts with energy stored as a voltage in a capacitor (top) or current in an inductor (bottom) and a fast-acting switch to release that energy, but there is obviously much more than that to a viable source. Source: SLAC National Accelerator Laboratory

The challenge of pulse power is not just achieving the balance between accumulating energy and then expending it as power in a brief burst. In most cases, the pulse rise time must be fast (microseconds or faster), so every subtle impediment to slewing, such as parasitic inductance or capacitance, must be identified and minimized.

There are also many smaller-scale applications which are not formally considered pulse-power situations but have some of their attributes. Consider a high-end processor (video, data, AI, or FPGA) which is in low-power states, then must quicky ramp up to handle a specific task. The current on the low-voltage core’s supply may ramp from tens of milliamps to tens of amps in microseconds and do so without overshoot or ringing. At the same time, the power source here is not a pulse-supply, but a “stiff” conventional power supply with good superior dynamics on its load-side regulation. That’s a challenge.

Note that not all pulse-power applications involve sophisticated designs or scientific experiments; some are pulse-like but on a much smaller scale. I have a small, basic Brother laminated-label maker which uses 8 AA batteries, Figure 3.

Figure 3 This Brother label maker takes 8 AA cells and has a barrel-connector port for an external AC/DC supply. Source: Newegg Inc.

Since I only use it every few months, it seemed prudent to not leave the batteries in, yet putting them in and removing them each time was a nuisance (plus, I had to find the eight batteries!). No problem, I figured: the unit has a barrel connector for an external AC/DC adapter. I went online and bought one rated for 9.5V/1.6A, which claimed to be a fit for this specific unit’s requirements; it had the right voltage, current, and barrel-connector size.

Perhaps I shouldn’t have been surprised, but the label-maker did not work with the adapter. I opened up the label maker so I could access and monitor the delivered supply voltage, Figure 4. (It’s all low voltage, so there was no danger; the only risk was shorting something out and ruining the unit.)

Figure 4 Accessing the power section of the label maker was fairly easy; remove a few screws and separate the unit’s top and bottom halves. Source: Bill Schweber

Its transient response was revealing: when called upon to deliver full current to drive the label-maker’s thermal printhead, the voltage dropped down to a few volts for about 50 milliseconds, then rose to nominal voltage and delivered the needed current. Unfortunately, that 50-ms window is when the printhead is expecting to receive full current for heating.

In contrast, the voltage output of the no-name alkaline AA batteries only dropped to 11.5 V—close to open-circuit nominal of 12.8 V (8 × 1.6 V)—and popped back to 12 V in about 10 msec. In other words, as a voltage source, these batteries were much stiffer and had a better transient response with respect load regulation, droop, and recovery.

For many designers, it’s not so much about pulse power in the classic sense as it is about the dynamics of load regulation. Some of the lessons of pulsed-power supplies such as use of capacitors and inductors to store and release energy do apply but others, such as having a long relaxation time between those high-current demands, may not.

Have you ever had a project where performance was stymied or intermittent due to a supply that could not support the load transients, even though its steady-state specifications were adequate? How did you diagnose the problem and then resolve it?

Bill Schweber is an EE who has written three textbooks, hundreds of technical articles, opinion columns, and product features

Related Content

Forget Tesla coils and check out Marx generatorsPulsed high-power systems are redefining weaponsWhat Is Digital Electricity?Power needs go beyond just plain voltage and currentReferences

NIF/LLNL:

Science, “With historic explosion, a long sought fusion breakthrough”, https://www.science.org/content/article/historic-explosion-long-sought-fusion-breakthroughNational Academies Press, “Review of the Department of Energy’s Inertial Confinement Fusion Program: The National Ignition Facility”, https://nap.nationalacademies.org/read/5730/chapter/6#22Lawrence Livermore National Laboratory, “The National Ignition Facility: Enabling Fusion Ignition for the 21st Century”, https://typeset.io/papers/the-national-ignition-facility-enabling-fusion-ignition-for-1dtoism225Pulse Power:

Photonics Spectra, “Powering the Pulse: Power Design’s Impact on Laser Performance”, https://www.photonics.com/Articles/Powering_the_Pulse_Power_Designs_Impact_on/p5/vo221/i1429/a68713MDPI, “Practical Design of a High-Voltage Pulsed Power Supply Implementing SiC Technology for Atmospheric Pressure Plasma Reactors”, https://www.mdpi.com/2076-3417/9/7/1451SLAC National Accelerator Laboratory, “Pulsed Power Engineering Basic Topologies”, https://uspas.fnal.gov/materials/09VU/PPE_BasicTopologies.pdfSLAC National Accelerator Laboratory, “Pulsed Power Engineering Introduction” (p. 7,8,9), https://uspas.fnal.gov/materials/09VU/PPE_Introduction.pdfHackaday, “Pulsed Power And Its Applications”, https://hackaday.com/2017/01/11/pulsed-power-and-its-applications/Springer, “Pulsed Power Technology”, https://link.springer.com/chapter/10.1007/978-4-431-56095-1_2FPGA and related high-power topics:

Microchip/Actel, “Power FAQs”, https://ww1.microchip.com/downloads/aemDocuments/documents/FPGA/ProductDocuments/SupportingCollateral/power_faq.pdfAnalog Devices, “FPGA Power System Management”, https://www.analog.com/en/design-notes/fpga-power-sys-mgmt.htmlAnalog Devices, “Care and Feeding of FPGA Power Supplies: A How and Why Guide to Success”, https://www.analog.com/en/analog-dialogue/articles/care-and-feeding-of-fpga-power-supplies-a-how-and-why-guide-to-success.htmlXilinx/AMD, “FPGA Power Requirements Overview”, https://www.xilinx.com/video/hardware/fpga-power-requirements-overview.htmlXilinx/AMD, “Spartan-6 FPGA Power Management”, https://docs.xilinx.com/v/u/en-US/ug394Texas Instruments, “Power Supply Design Considerations for Modern FPGAs”, https://www.ti.com/lit/an/snoa864/snoa864.pdfPulse power and transient loads: a very different world由Voice of the EngineerComponentsColumn releasethank you for your recognition of Voice of the Engineer and for our original works As well as the favor of the article, you are very welcome to share it on your personal website or circle of friends, but please indicate the source of the article when reprinting it.“Pulse power and transient loads: a very different world”